Messer - Air separation unit - CryoGan - Messer Group Anwendungstechnik

Breadcrumb

---CRYOGAN

CRYOGAN

CRYOGAN NITROGEN GENERATORS – A PARTICULARLY COST-EFFECTIVE SOLUTION

CryoGAN top 2606

CRYOGAN

In order to meet the demand for larger quantities of nitrogen at optimal costs, and the more severe requirement for CO2 footprint reduction, Messer has developed its CryoGAN nitrogen generator concept. CryoGAN is a special nitrogen production unit that operates on the principle of cryogenic air separation, but tailor made for the customer requirements in each single case.

Messer develops and builds the CryoGAN generators in-house. The units are modular in design and offer a graduated capacity range from 300 Nm3/h to 15 000 Nm3/h. The layout is based on the Messer safety and reliability philosophy which has been applied for over 20 years in operating air separation plants for the supply of customers world-wide.

The nitrogen generator has been designed for the ease of operation and low maintenance. In order to minimize personnel and operating costs, all equipment and process controls will be operated and monitored by a computer control system, therefore all the plants are remote controlled.

Major feature of CryoGAN nitrogen generator:

Verschachtelte Anwendungen

Major feature of CryoGAN nitrogen generator ( 1 column)

- Capacity: 300 to ⩾15,000 Nm3/h nitrogen

- Purity: 99.999 to 99.9999 (2.0 to 0.2 ppm O2)

- Supply pressure: 4 -10 bar (g)

- Operating range: 100-50%

- Specific energy: 0.22-0.35 kWh/Nm3

- Availability >99.9%

Major feature of CryoGAN 250624

- Reduction of CO2 emissions

- Configured for CAPEX and/or OPEX

- Designed for 24x7 operation

- Safe, reliable, simple to operate, easy to maintain

- Plug-and-play installation

- Short construction time

Reliable backup supply GAN

Reliable Backup Supply

A reliable supply from a backup source – just in case it is ever needed – is the icing on the cake of any on-site concept, allowing the customer to sleep soundly in terms of gas supplies, even when there are maintenance downtimes, power outages or other unforeseen events. Our regional logistics network with centrally managed European coordination, combined with sophisticated production planning, ensures that every customer receives a reliable supply of technical gases from Messer, even during planned and unplanned downtimes.

Optional co-products for nitrogen generator:

- Compressed dry air

- Residual air with high oxygen content

APPLICATIONS of CryoGAN

APPLICATIONS

The nitrogen produced by the CryoGAN nitrogen generator is ideal for the chemical, oil and gas, automotive, agricultural and food industries, electronics and other industries including production of lithium-ion batteries.

Based on the requirements, wishes of the client and the agreed conditions, the CryoGAN nitrogen generator with a backup system will be installed on the customer´s premises. The system allows to guarantee the continuous supply of the customer's production with gas in terms of required volume and pressure

Teaser Fluid Catalytic Cracking Duplikat 2

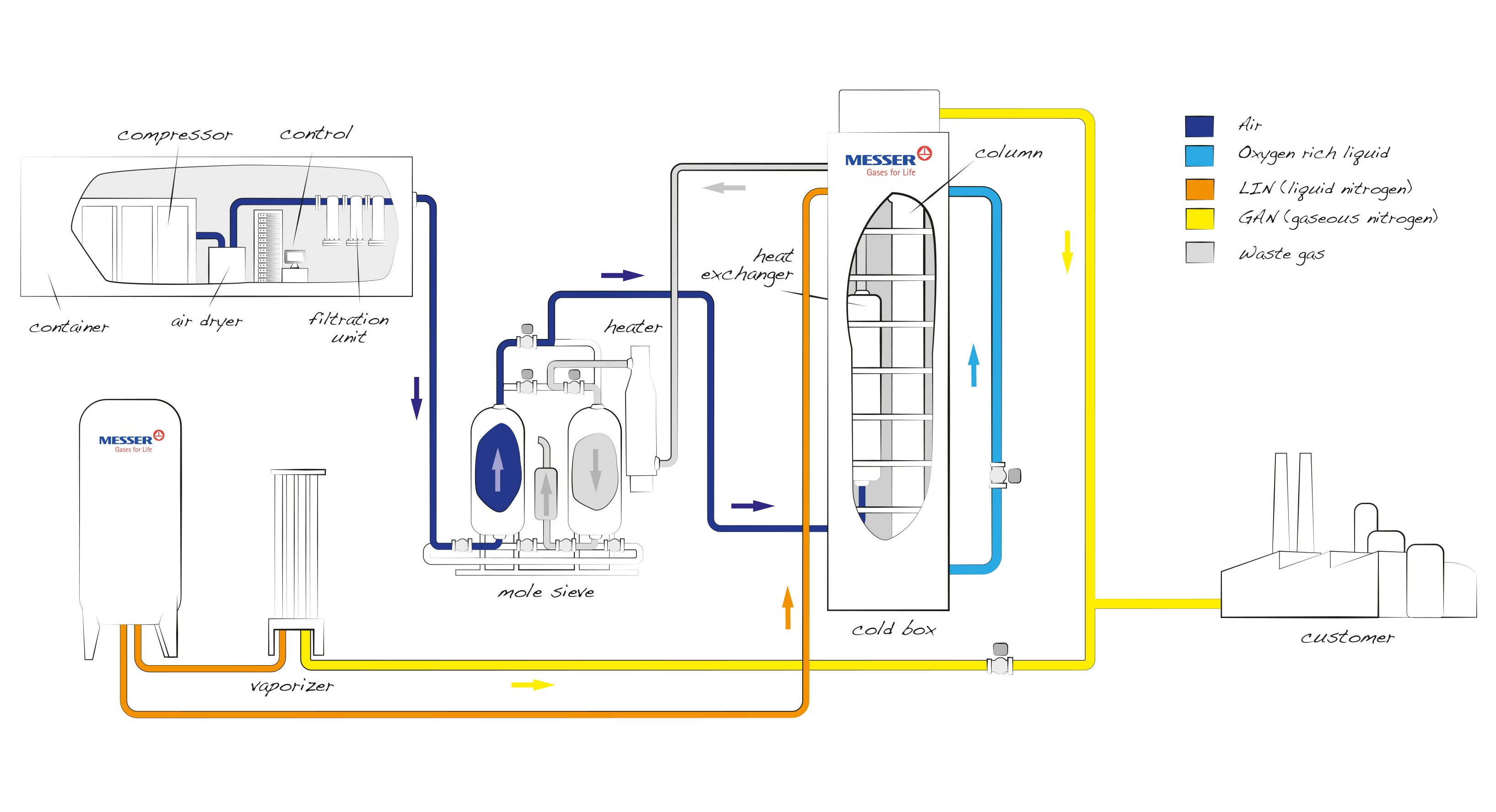

Diagram of a CryoGAN nitrogen generator

Diagram of a CryoGAN nitrogen generator

Powerful as a matter of principle Irrespective of their capacity, the basic principle is the same for all CryoGAN nitrogen generators and consists of the following components

Asset-Herausgeber

Contact form for every page

Sprechen Sie uns an

Was ist Ihr Anliegen?