Messer - Oxygen generation - VPSA - Messer Group Anwendungstechnik

Breadcrumb

VPSA - top

VPSA

VPSA Oxygen Generators (Vacuum Pressure Swing Adsorption)

OXYGEN GENERATOR top

VPSA

Oxygen generator VPSA is Messer’s top-notch solution for on-site Oxygen production, providing high reliability and best-in-class performance, if oxygen purity in the range of 90 % to 94 % is required. A highly efficient source of Oxygen for use in a variety of industries such as glass, metallurgy, cement and chemicals.

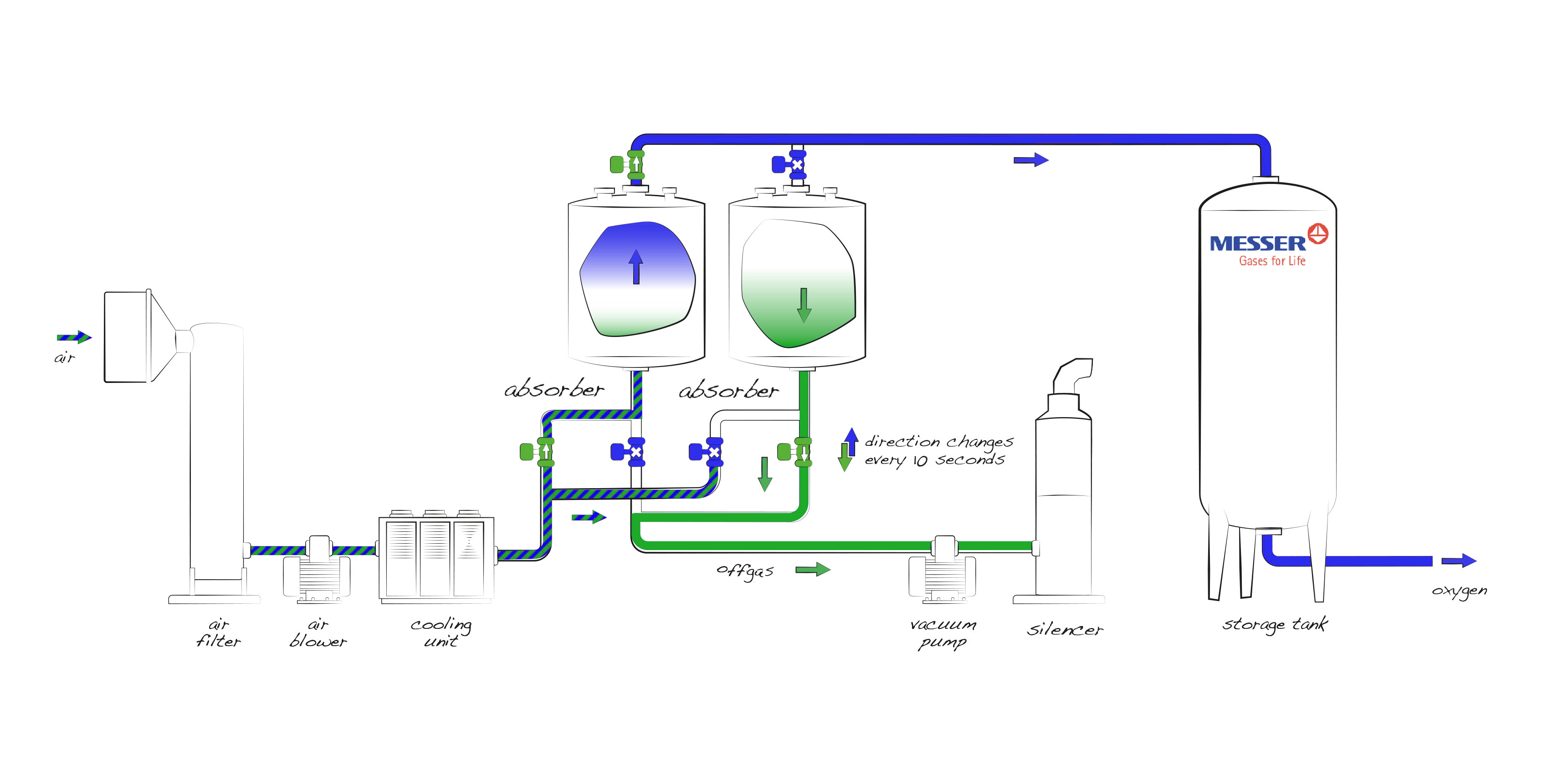

The operating principle of VPSA units is based on the selective adsorption of certain components of gas mixtures. In this case, the adsorption rate plays a significant role in the operation of such installations. Since the cycle duration is short, adsorbed impurities saturate only the surface layers of the adsorbent granules, without having time to penetrate into the deeper layers. In this case, it is easy to carry out subsequent desorption by pumping out the accumulated impurities using a vacuum pump.

The plant layout is based on the Messer safety and reliability philosophy which has been applied for over 20 years in operating air separation plants for the supply of customers world-wide.

The oxygen generator VPSA has been designed for the ease of operation (under normal conditions) and low maintenance. In order to minimize personnel and operating costs, all equipment and process controls will be operated and monitored by a computer control system.

The plant is designed for automatic control and automatic operation under normal operating conditions.

The VPSA Oxygen generator is designed to produce Oxygen in gaseous form.

Verschachtelte Anwendungen

OXYGEN GENERATOR VPSA

OXYGEN GENERATOR

- Capacity: 400 up to 5.000 Nm3/h Oxygen

- Purity: 90 – 93 (94) %

- Supply pressure without booster: 0,2 bar(g)

- Operating range: 100-40%

- Low specific power: 0,36 kWh/Nm³ ( 100 % O2 )

- Modular Design feasible

OXYGEN GENERATOR benefit

Benefits for our Customers:

- Low long-term operating cost

- Designed for 24x7 operation

- Safe, reliable, simple to operate, easy to maintain

- Short construction time

- Significant Reduction of CO2 emissions

OXYGEN GENERATOR back up

Reliable backup supply

A secure supply from a backup source – just in case it is ever needed – is the icing on the cake of any onsite concept, allowing the consumer to sleep easy with regard to the gas supply, even when there are maintenance downtimes, power cuts or other unforeseeable events. Our regional logistics network with centrally managed Europe-wide coordination, combined with sophisticated production planning, ensures that every single customer receives a reliable supply of technical gases from Messer, even during planned and unplanned downtimes.

APPLICATIONS of VPSA 2606

APPLICATIONS

Oxygen produced by the VPSA Oxygen generator produces Oxygen, which allows it to be used for glass and metal production, fisheries, laser cutting, water purification and many other production processes. Oxygen produced using the VPSA Oxygen generator is ideal for the chemical, oil and gas, automotive, pharmaceutical, agricultural and food industries, electronics and other industries including production of lithium-ion batteries.

Based on your requirements and the needs of your production, we help you find the optimal solution using our extensive knowledge of the specifics of your industry, gained over many years of experience.

PROCESS DESCRIPTION

PROCESS DESCRIPTION

The VPSA Oxygen generator production line consists of the main technological equipment:

The VPSA Oxygen generator production line consists of the main technological equipment:

VPSA our goal

Our goal is to provide you with uninterrupted supply to your production at low production costs and reduced CO2 emissions with the Nitrogen parameters you require, such as constant temperature and Nitrogen pressure.

MESSER is chosen by thousands of customers around the world

Asset-Herausgeber

Teaser Fluid Catalytic Cracking Duplikat 2 Duplikat 3

Contact form for every page

Sprechen Sie uns an

Was ist Ihr Anliegen?